Spinks India machines & support

All aspects of the printing workflow- from a single source

At Spinks World we distinguish ourselves as a leader in the printing solutions sector, offering an unrivaled combination of high-quality printing inks , consumables and state-of-the-art printing equipment , and automations.

We facilitate your operations

Our role as a comprehensive solutions provider extends beyond the point of sale. Post-purchase, we are committed to addressing your technical queries with expediency and precision. Our adept service technicians are available globally to provide on-site assistance or to deliver prompt remote troubleshooting through real-time remote maintenance services. Read More

Our unique position as both a provider of premium inks and advanced ..... pad printing, screen printing, and spray coating equipment, automations and customisations sets us apart, making us the preferred choice for businesses seeking comprehensive printing , coding and laser etching solutions

Select

Spinks Group

for expert printing support

EPIC Pad printing solutions

Industry leading Automations and SPMs.

Our EPIC pad printers feature top-tier consistency and integrated efficiencies, delivering substantial savings in time and costs. Offering a diverse range of pad printing machines: single to multi-color, manual through fully-automated. .

Spinks Impex of spinks Group specializes in creating bespoke automated systems that are meticulously crafted to cater to the varied needs of our clients. At EPIC pad printing solutions , We excel in automation, assembly, and customization, transforming concepts into practical solutions. As experts in automations, feeding, handling, robotics, and specialized pad printing machinery, we bridge the gap from design to engineering . With over 30 years of delivering unwavering quality, Spinks World is synonymous with reliability. (Patent pending no. 202311029799)*

Screen printing machines

Empowering creativity, one print at a time.

Excellence in Glass Printing

As the premier distributor in India for Koenig & Bauer Kammann GmbH, Spinks India is recognized for delivering state-of-the-art German industrial printing technologies since 1955. Renowned for innovation and quality, Kammann's screen printing machines define precision, efficiency, and adaptability. A global leader for finest glass printing solutions, Kammann specializes in decorating a variety of containers and hollow ware for various industries. For high-level performance and high-volume production needs, Kammann’s equipment is the preferred option.

- 1. Bespoke screen printing machines from Spinks Group

- 2. Best for transparent glass screen printing

- 3. No pin hole printing

- 4. Flatbed and rotary screen printing machines

- 5. Special purpose automatic / semi automatic screen printing machines

- 6. Best for screen printing of logos, pictograms, graphics and other applications requiring uniform ink layer.

- 7. Versatile, stable, simple and easy to operate

- 8. Ideal for printing on plastic, glass , medical devices and components , house hold goods, touch panels and technical fabrics.

- 9. Optional : registration camera , servo drives, UV curing units etc.

Introducing the All-New Flatbed UV Digital Printing Machine

Redefining Precision and Quality for Glass and Beyond!

Transform your printing experience with the Farbajet Flatbed UV Digital Printing Machine. Combining precision, quality, and versatility, it excels on materials like glass, wood, and more. Advanced UV curing ensures instant drying and vibrant, durable prints, while features like industrial-grade print heads, anti-static bars, and inline primers boost productivity and creativity.

Engineered for perfection, the Farbajet delivers photo-realistic prints with customizable ink options, including white and varnish. With auto-height detection, anti-collision technology, and silent operation, it meets the demands of industries from architecture to automotive. Step into the future of digital printing with unmatched speed, reliability, and quality.

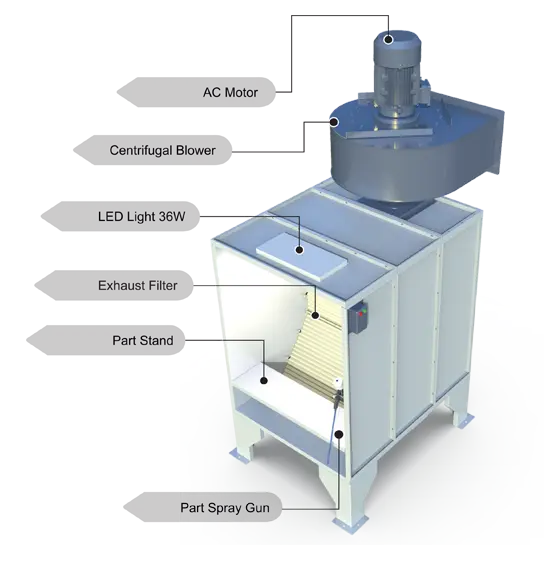

Spray coating equipment

Empowering creativity, one print at a time.

- 1. Dry filter spray booth with Swiss technology

- 2. Smooth internal surface/ walls for easy cleaning

- 3. Easy to install

- 4. High efficiency , reliable and patented technology integration

- 5. Easily decomposable and disposable filters

- 6. Environment friendly

- 7. The sophisticated filtering system achieves an impressive 98% filtration efficacy coupled with a robust loading capability. This composite filter comprises two dense layers of "Kraft" paper, meticulously punched and pleated, then bonded. A layer of polyester reinforces the structure at the rear, enhancing its overall ability to filter particles.

Cliché plate etching equipment.

Transforming clichés into masterpieces, one etch at a time.

Our catalog presents an extensive selection of clichés, spanning from untreated to print-ready states, inclusive of laser-etched and exposed varieties, all precision-engineered in-house to seamlessly conform with the pad printing process.

The term "Cliché making lasers" denotes the laser engraving systems designated for the fabrication of cliché plates in pad printing applications. These systems meticulously engrave the desired image onto the cliché surface, facilitating the transfer of ink to the printing substrate. Selection of cliché material hinges upon multiple parameters such as intended use, while the etching depth on a cliché plate is tailored to the specific product application. With Markolaser's cliché etching technology, it is feasible to achieve etching depths ranging from 4-5 microns to 60-70 microns on 60 HRC MS plates.

Markolaser's Cliché Maker is instrumental in producing Preciteel Clichés, serving both decorative and practical pad printing requirements. These clichés are versatile across all volumes and compatible with any pad printing machinery, offering options for halftone or line engraving and suitable for both flat and rotary printing modalities.

.jpg)